How the Mister Minit Sharpening Process Works

Precision. Care. A Sharper Standard.

At Mister Minit, sharpening isn’t just a service, it’s a craft.

Every tool we sharpen, whether it’s a chef’s knife or a groomer’s clipper blade, receives expert care from trained technicians using professional-grade equipment. Our sharpening process is precise, safe, and tailored to the exact needs of your tool, because no two blades are the same.

Here’s how we bring your tools back to life, edge by edge.

Our 5-Step Sharpening Process

1. Inspection & Edge Assessment

We begin by inspecting each tool for:

- Blade condition (nicks, chips, rust, burrs)

- Edge type (straight, curved, serrated)

- Blade material and hardness (carbon steel, stainless, titanium)

- Intended use (kitchen, garden, grooming, etc.)

This ensures we choose the correct grit, angle, and method for optimal results.

2. Sharpening on Precision Wheels

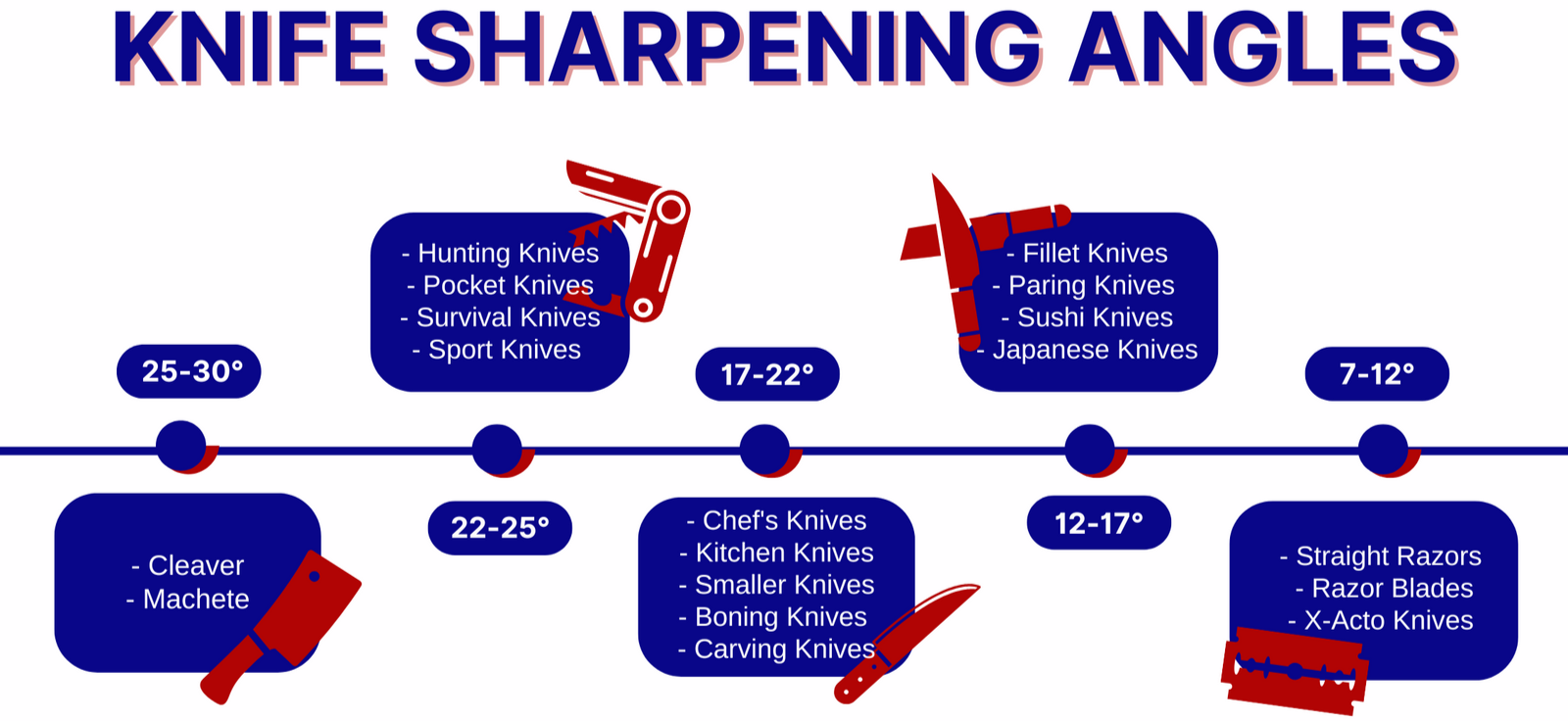

Based on your tool type, we carefully grind and reform the edge using:

- Coarse wheels (for chipped or very blunt blades)

- Medium/fine wheels (for routine resharpening)

- Variable sharpening angles (e.g. 15° for chef knives, 20°–25° for garden tools)

- Technicians maintain cooling protocols to prevent blade overheating, which can ruin edge retention or damage heat treatment.

3. Honing & Edge Refinement

After the base sharpening, we hone the blade using fine abrasives or rods to:

- Align the microscopic teeth of the edge

- Remove burrs

- Improve smoothness and edge retention

- This step ensures your tool cuts cleanly and consistently from the first use.

4. Polishing & Final Testing

We polish the cutting surface for:

- A cleaner finish

- Reduced friction during use

- Visual inspection of evenness and reflection

- Where applicable, we test tools on appropriate materials (e.g. paper slice test, strand snip test) to ensure sharpness is restored.

5. Final Quality Check

Before your tool is returned, we:

- Confirm edge symmetry and sharpness

- Check for any remaining defects

- Clean the tool (external wipe-down or light oiling)

- Safely repackage or case the item (where applicable)

Our Equipment

We use professional-grade sharpening systems including:

- Diamond and ceramic wheels for controlled material removal

- Angle guides for consistent bevels

- Honing rods and polishing belts

- Cooling systems to preserve blade temper

- Protective clamps and shields for safety and control

- Everything is maintained in-store, with technicians trained to sharpen by both feel and measurement.

Not All Tools Are Treated the Same

Each tool type has unique sharpening needs:

Craft Scissors:

- Precision sharpening of convex or bevel edges

- Careful protection of ride line and alignment

- Tension adjusted after sharpening

Kitchen Knives:

- Sharpened based on blade style (Japanese or Western)

- 15°–20° edge angle depending on hardness

- Honed to remove microburrs

Garden Tools

- Edges reshaped for impact durability

- Angle varies by tool (e.g. loppers vs axes)

- Hinges oiled, blades polished

Clippers

- Sharpened flat and evenly for proper motion

- Teeth aligned and deburred

- Blade lubricated post-service

- Every blade gets the attention it deserves.

Our Quality Promise

When you sharpen with Mister Minit, you get:

- Professional equipment and technique

- Safe handling and precision edge control

- Consistent, repeatable results

- Honest advice from experienced staff

- Free edge checks anytime

If you’re not satisfied, we’ll make it right.